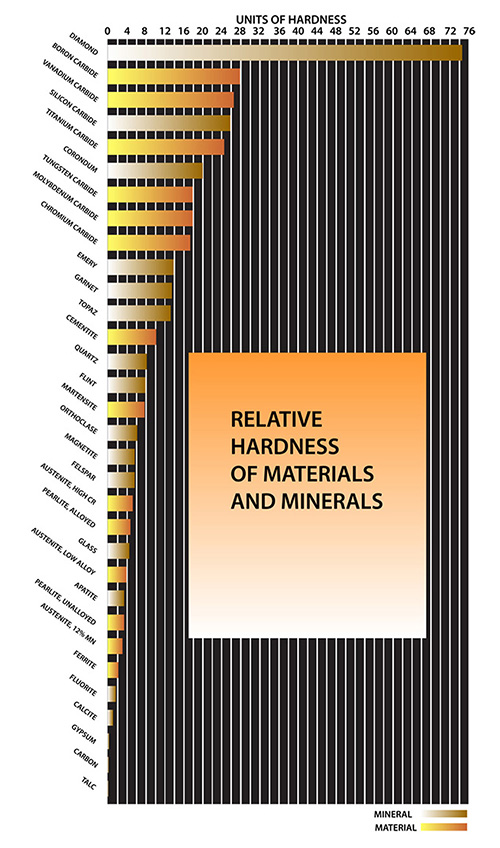

Lile ibatan ti Awọn ohun elo ati Awọn ohun alumọni

-

- 1. Diamond

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silikoni carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emery

- 11. Garnet

- 12. Topasi

- 13. Cementite

- 14. kuotisi

- 15. Flint

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, ga CR

- 21. Pearlite, Alloyed

- 22. Gilasi

- 23. Austenite, Low alloy

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Erogba

- 32. Talc

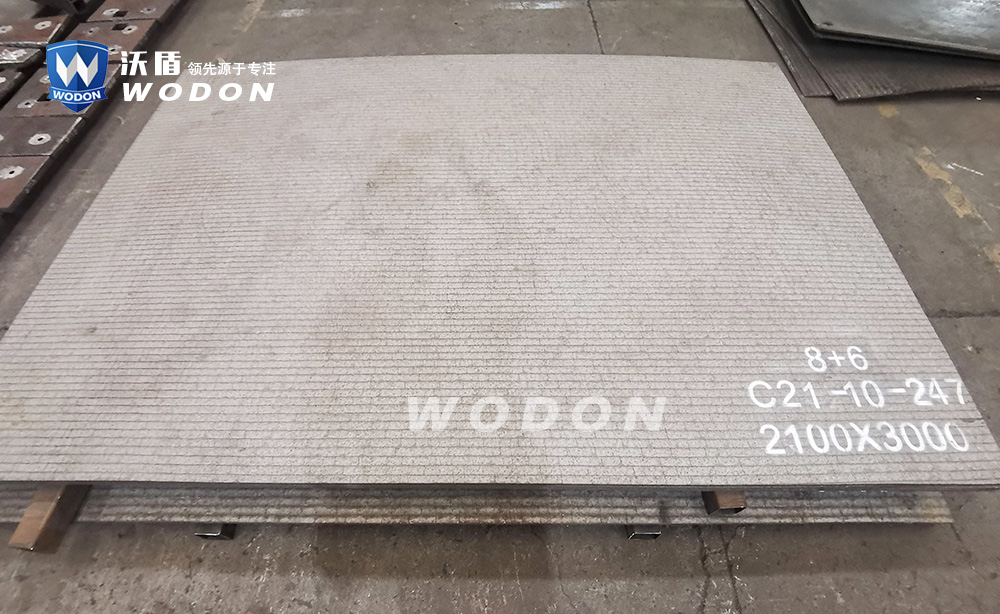

- Wodon jẹ amọja ni iṣelọpọ Chromium carbide overlay wear awo, a gba imọ-ẹrọ alurinmorin arc submerged eyiti o ni akoonu Cr diẹ sii ti o wa lati 25% si 45%. ida iwọn didun carbide lori microstructure jẹ loke 50% ati pe o pọju líle ti patiku lile jẹ HV1800. ọna ASTM-G65 A wa labẹ 0.16g.

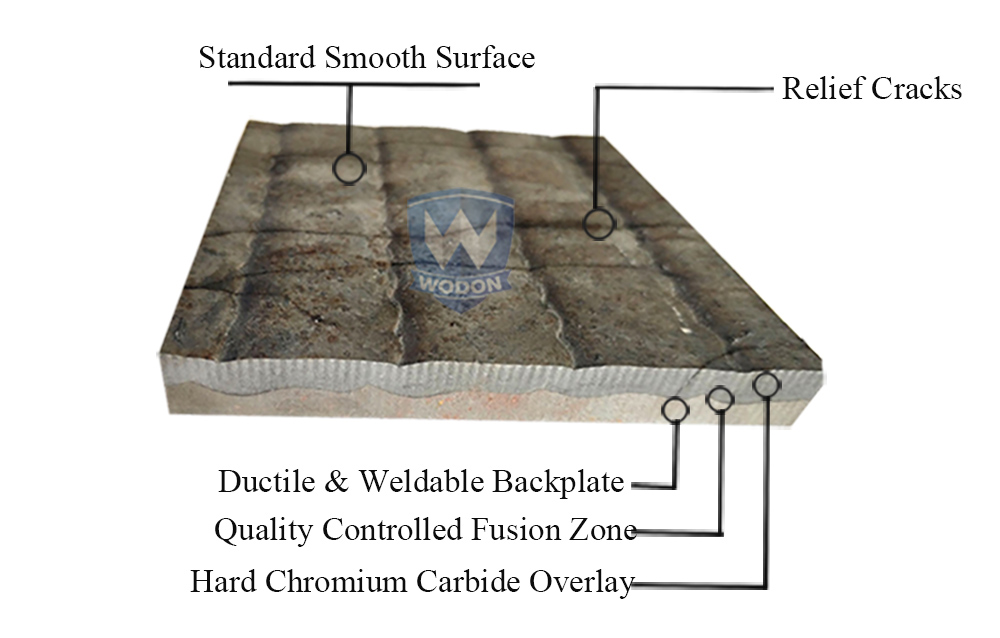

- Awo bimetallic Chromium Carbide:

- Alabọde/Low erogba irin +Aawọn fẹlẹfẹlẹ sooro brasion →Chromium carbide bimetallic awo pẹlu irin imora

- (Q235/Q345B + Chromium Carbide agbekọja →Chromium carbide bimetallic awo nipasẹ Submerged arc tabi Ṣii arc alurinmorin

- imọ ẹrọ)

- Ẹ̀kúnrẹ́rẹ́:

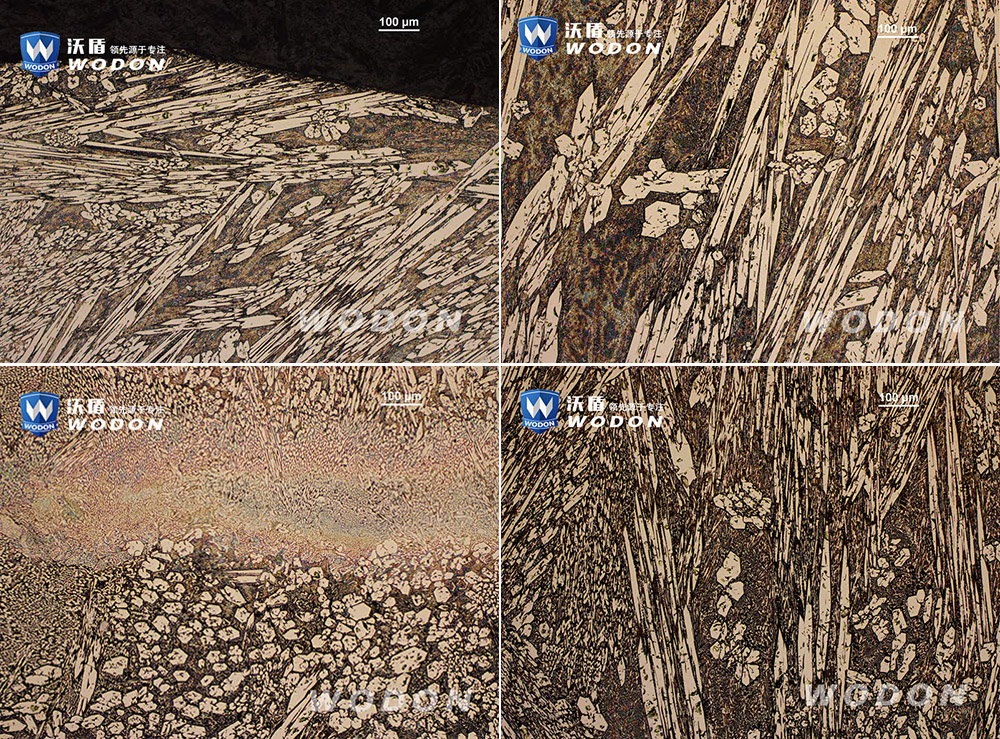

- Layer sooro yiya ni iye giga ti awọn patikulu lile carbide chromium. Awọn patikulu wọnyi ti pin ni deede jakejado Layer, ṣiṣẹda microstructure to lagbara. Lile jẹ HRC 58~65ati ki o da lori awọn apọju ká sisanra.

- Awọn eroja akọkọ ti awo Wodon jẹ C (%): 3.0 ~6.0 ati Kr (%): 25 ~ 45. Iwọn kemikali yii ṣe abajade ni iye nla ti Cr7C3 chrome carbide lile patikulu. Lile micro-lile (to HV1800) ti awọn patikulu wọnyi jakejado Layer yoo ṣe iṣeduro dada sooro asọ nla kan.

- Awọn agbekọja ati ipilẹ awo ni o wa metallurgical imora. Ikọja naa yoo wọ inu awo ipilẹ ni iwọn 0.8 ~ 1.8 mm, de ọdọ 350 Mpa ninu awọn idanwo wa.

-

- WD1200 wọ awole ṣee lo fun ohun elo abrasion ti o lagbarations.

- * Chromium carbide agbekọja yiya sooro awo

- * Nipa submerged aaki alurinmorin ọna ẹrọ

- * Iṣọkan Kemikali: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 ida iwọn didun nipa 50%

- * Awọn sisanra ti yiya sooro Layer le de ọdọ 50 mm

- * Idaabobo igbona titi de 600°C

- * Agbegbe sooro wiwu ti o tobi ju 1400*3000mm, 1400*3500mm, 2100*3500mm

- * Dara flatness pẹlu dan dada

- * Lile: HRC58-65(650-720HV)

- Awọn awo wọnyi ni lilo pupọ ni Iwakusa, Simenti, Agbara, Edu, Port, Awọn turbines afẹfẹ ati ile-iṣẹ Metallurgical.

-

Akoko ifiweranṣẹ: Oṣu Kẹsan-27-2021